A linear stage stabilizes the axis of motion for an object being moved by a motion system. The sliding motion produced has led some people to refer to the device as a linear slide, which is the linear motion bearing component of the stage. Parts of the linear, or translation, stage include a platform and base linked by the linear motion bearing and a guide. The system allows for motion translation along a single axis, whether it is the X, Y, or vertical Z axis.

The platform of a linear stage always moves in relation to its base. Motion is limited to one axis by the device’s guide. Types of guide include ball bearing styles, which provide short travel distances and low capacities for weight and are the most inexpensive. Flexure guides are highly accurate and don’t wear, but have a short travel range. Crossed roller bearing, high-capacity cylindrical sleeve, and dovetail guides are also common styles used with a linear stage.

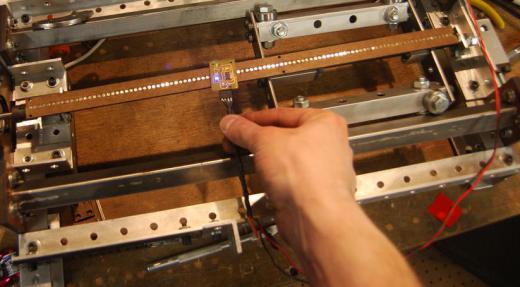

Linear actuators in a translation stage control the position of the platform as it moves. When in a manual configuration, a control knob on the lead screw indicates the stage’s angular position. In optics applications, precision stages require higher accuracy than a lead screw allows for, so a fine-pitch screw or micrometer is attached to metal pad on the platform. Motion can also be controlled by a stepper motor, which is set to move in increments referred to as steps in motion applications.

A DC motor with an encoder can be integrated into a linear stage. Fixed increment motion does not apply to this type, so a scale is integrated into the stage and the encoder measures the stage position in relation to the scale. Positioning data is relayed to a controller that automatically moves the stage into pre-set positions. Systems requiring more than one axis of motion can combine linear stages, such as a two-axis stage used for microscopes. If vertical motion is needed, a three-axis stage is used.

For motion systems, accuracy is important. An Abbe error is a common displacement resulting from angular errors in the system. Other errors include pitch, roll, and yaw, and the accuracy of the X and Y axes is dependent on the orthogonal alignment of the other axis. A linear stage can also include rotary and tilt controls, allowing for up to six axes of motion.